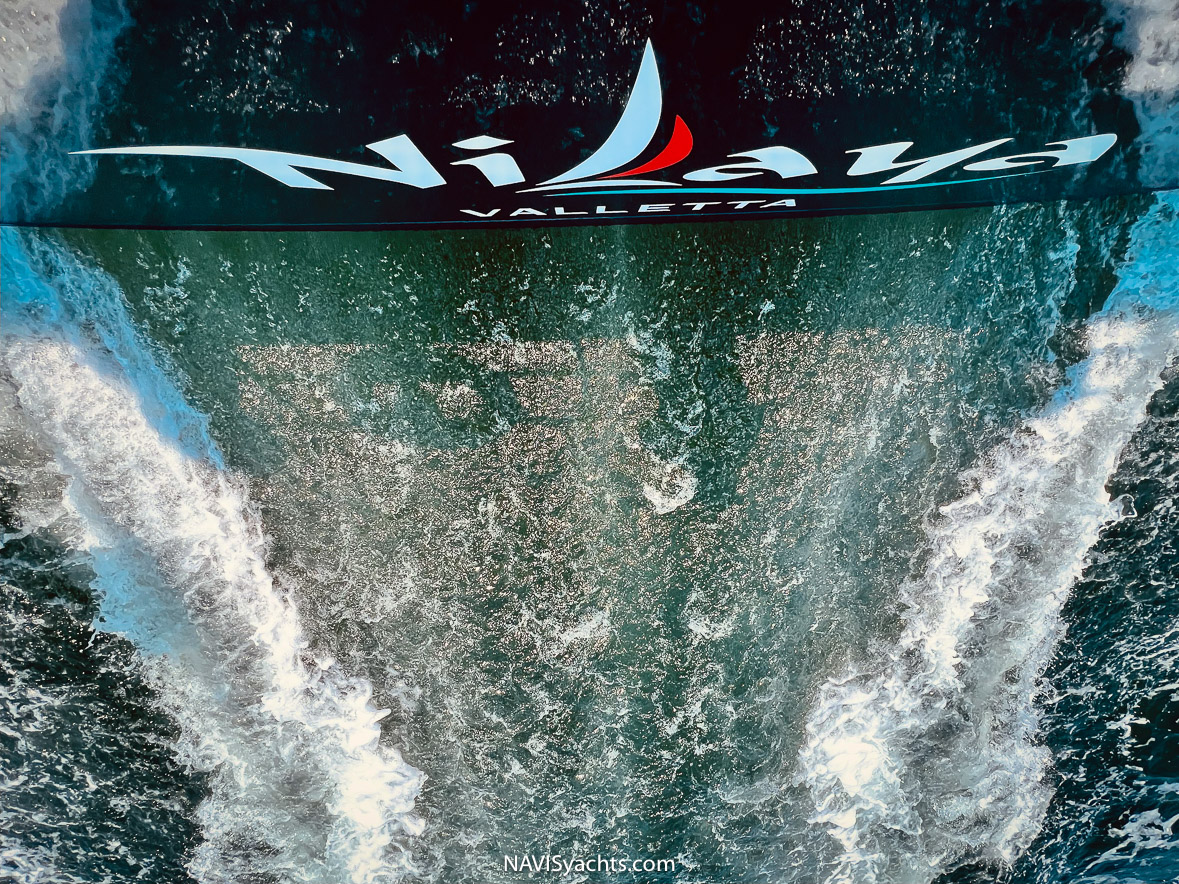

Royal Huisman’s Luxurious Supersailer Nilaya Poised to Break Records

How long does it take to cross the Atlantic Ocean on a sailing yacht? For Royal Huisman’s 47-meter Nilaya, that would be ten days, give or take an hour or two. Tenerife in the Canary Islands to English Harbour in Antigua, Nilaya covered 2,775 nautical miles. In late November, sailing in mostly Beaufort 3-4 seas, this distinctive Panamax sloop averaged 11.6 knots with a top speed of more than 20 knots. That is fast, with a capital “F.”

The owner sailed dinghies as a child, graduating to a series of Swans. For the past dozen years, he sailed and raced a 34-meter Nauta Design and Reichel/Pugh yacht built by Baltic Yachts. That predecessor, also named Nilaya, accumulated an impressive collection of awards and race hardware. Sanskrit for “blissful home,” the owner and his wife always enjoyed time on board the yacht, but over the years the couple compiled a wish of improvements they felt would make their time on board even more pleasant.

With thousands of sea miles aboard everything from dinghies to elite custom racing yachts, the owners came to Royal Huisman with a reasonable list of requirements for a new yacht. They again requested Nauta Design and Reichel/Pugh for the new build. Joined by the owner’s seasoned project manager Nigel Ingram, MCM Newport, they set out to define the parameters of the next Nilaya.

The Owner’s Brief

Speed, safety, reliability, and serenity were all high priorities as the owner sought “more comfort in a fast yacht that can win a superyacht regatta.” Asking a yacht to be fast in light wind while elevating comfort and diminishing noise required a critical look at every system in a synergistic, holistic way. Data sharing and planning among the designers, architects, and builders proved the key to success in creating this new Nilaya, the lightest, and perhaps even the fastest, aluminum sailing superyacht among her 47-meter peers.

A Solutions-Based Approach to Weight in Featherlight™

Prior to entering into an agreement, the owner requested proof that Royal Huisman could build this lighter yacht to fulfill the new brief. Fortunately, technology had advanced a great deal since the first Nilaya was built. Royal Huisman created an engineering approach based on the European Space Agency methodology.

Employing FEA, finite element analysis, Royal Huisman was able to direct the ideal materials and thicknesses for exact stresses and loads on every part of the hull and deck. The previous boat was all carbon. It won its share of important regattas and was fun to sail, but it was not as comfortable, nor as quiet or as luxurious, as the owners desired.

A year of design and testing leading to a two-year build time, the combination of CFD, aka computational fluid dynamics, in concert with analytic hydrotools and other innovative design testing technologies were applied to the design. That intensive analysis resulted in an exceptional sailing yacht considered the most technically advanced ever delivered by Royal Huisman. The result is that Nilaya is a true aluminum / carbon hybrid.

Diving even deeper, Reichel/Pugh called upon a sophisticated RANS code analysis used to predict turbulence created by the boat’s underwater structures. RANS, or Reynolds Averaged Navier-Stokes equations, looked closely at the flow around the underwater structures, including the props, rudders, keel, and hull. The RANS model is similar to programs used to create efficient submarine hulls, confirming optimal design.

Further critical evaluation of Nilaya’s design involved decisions whether to use aluminum or carbon for a particular piece, often resulting in a truly hybrid solution. Sometimes the choice found Alustar aluminum, an alloy 20 percent stronger than typical aluminum, backed with carbon, resulting in significant weight savings.

Careful monitoring shaved 11 percent from the construction weight compared to typical yachts of this size. Another 4 percent was saved through revision of choices in equipment, interior furnishings, and sail and mechanical systems. Titanium hardware, carbon door frames, and a carbon fiber Rondal spreader design all contributed to a reduced yacht weight.

Further weight savings were made to ensure interiors were quiet, yet still luxurious, and very high quality. Sound attenuation studies led to sophisticated composite insulation panels of cork, foam, honeycomb, and other materials, making Nilaya a dream for passengers.

A total 15 percent reduction in weight without sacrificing stiffness or quality while improving on the noise levels typical of carbon fiber hulls just begins to describe the thorough critical analysis of this construction approach. The process proved so distinctive, combining a library of weight-saving solutions, that Royal Huisman gave this reliably repeatable process the name Featherlight™. Thus, Nilaya steps out of the mold of her predecessor, changing the way sailing yachts are designed and built at Royal Huisman. Nilaya, In the words of Jim Pugh, “breaks the dawn of a new era in superyacht design.”

With a dedicated weight engineer and a bevy of weight studies, Royal Huisman provided extensive reports and spreadsheets detailing the weight of every part of the yacht. Rondal created a new generation hybrid captive winch with aluminum frame and carbon drums weighing in at 1,200 kg vs the 2,646 kg typical of comparable winches. Suffice it to say the team left no stone unturned in creating the lightest, fastest, stiffest yacht possible. “They really chased the details,” Nigel Ingram noted.

To ensure the design aesthetics, engineering, and ergonomics all served the owner’s brief, Royal Huisman took an extra step after the virtual models were presented. They emptied out their huge paint hall and proceeded to build a full-scale model of the yacht, mast to swim step, out of synthetic material. They then spent several days with the owner, his representatives, and his racing team, examining every step, every seat height, every winch, every hardware placement, every light, every grabrail and every helm station, exploring any adjustments that might be necessary to deliver the ideal functional, comfortable, luxurious yacht.

Photos: Nico Martínez, Carlo Borlenghi - Studio Borlenghi, Rondal | Words: KL Turner